|

Outline

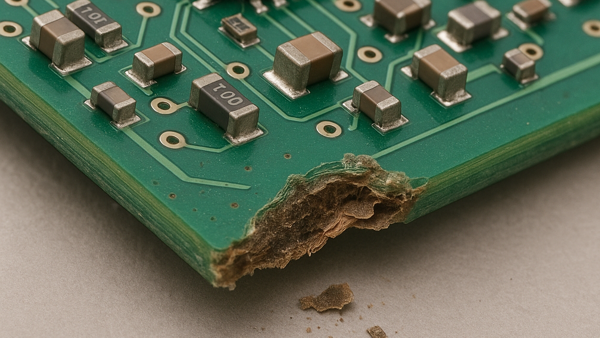

This procedure is used to repair minor damage to circuit base board material. Scrapes and scratches in the base board material may be caused by accidents during handling. Burns in the base material may be caused by improper use of soldering and desoldering tools.

|

||||||||||||||||||||||||||||||||||||||||||||

|

Procedure

Procedure

Evaluation

|

||||||||||||||||||||||||||||||||||||||||||||

Images and Figures

Base Material Repair, Epoxy Method

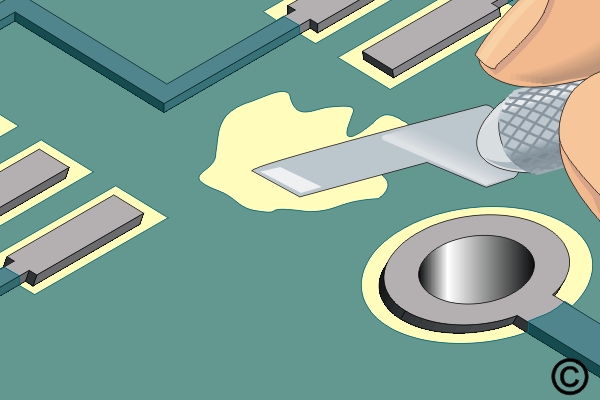

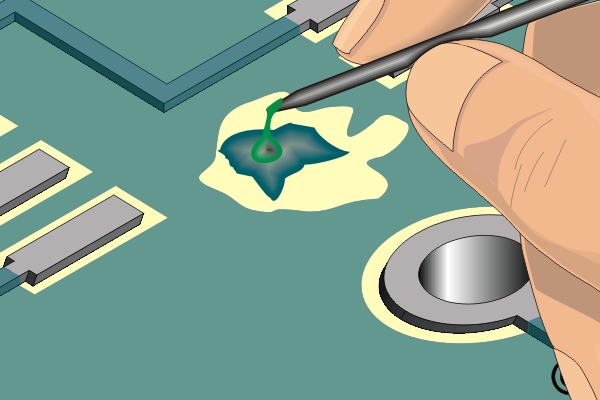

Figure 1. Scrape away damaged base board material with a knife.

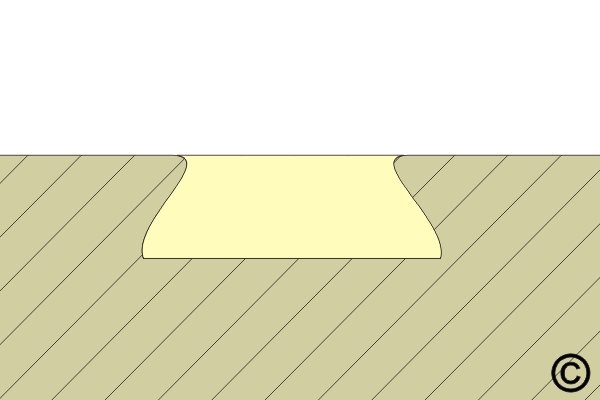

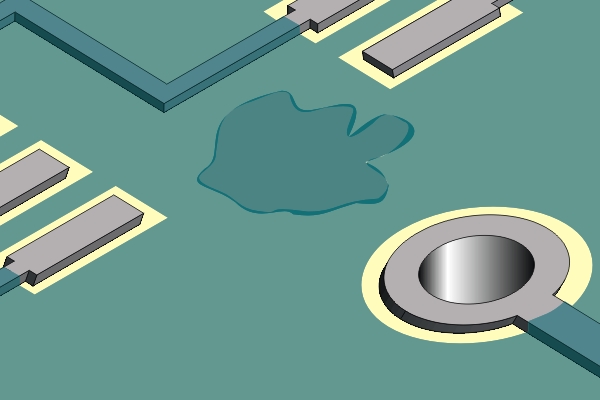

Figure 2. An undercut, to enhance mechanical strength, may be desired for class 3 product.

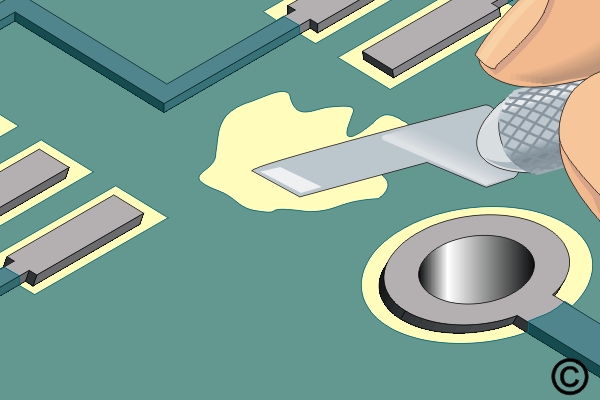

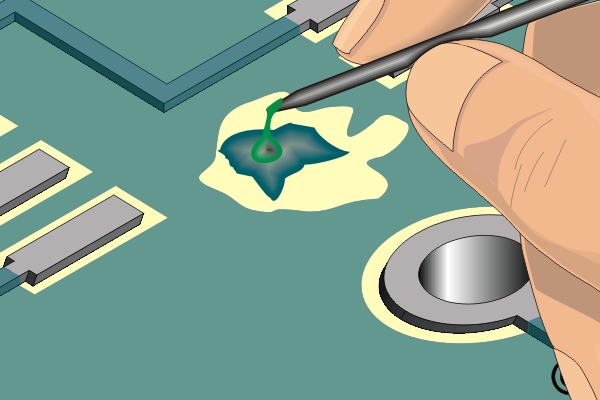

Figure 3. Apply the epoxy with a mixing stick sharpened at the end.

Figure 4. For large areas, apply the epoxy with a foam swab to create a texture.

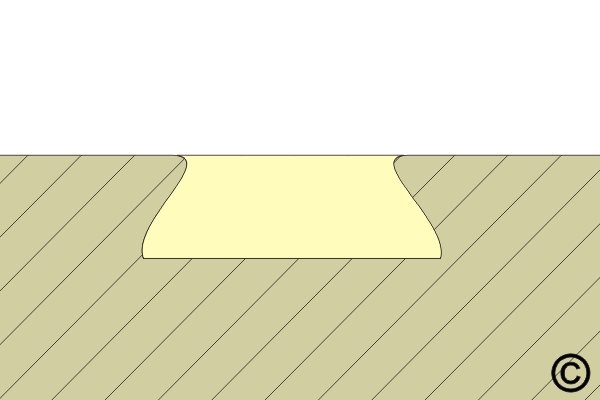

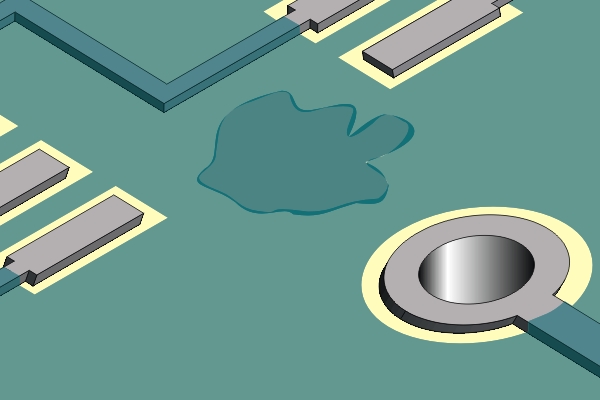

Figure 5. Completed repair.

|

||||||||||||||||||||||||||||||||||||||||||||

3.5.1 Base Material Repair, Epoxy Method

Procedure covers minor repair of damaged base board around edges on circuit board assemblies.

Minimum Skill Level: Advanced

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Base Material Repair, Epoxy Method

Scrape away damaged base board material with a knife.

An undercut, to enhance mechanical strength, may be desired for class 3 product.

Apply the epoxy with a mixing stick sharpened at the end.

For large areas, apply the epoxy with a foam swab to create a texture.

Completed repair.

This clear, low-viscosity, superior-strength epoxy is ideal for many circuit board repair and rework uses.

LEARN MORE

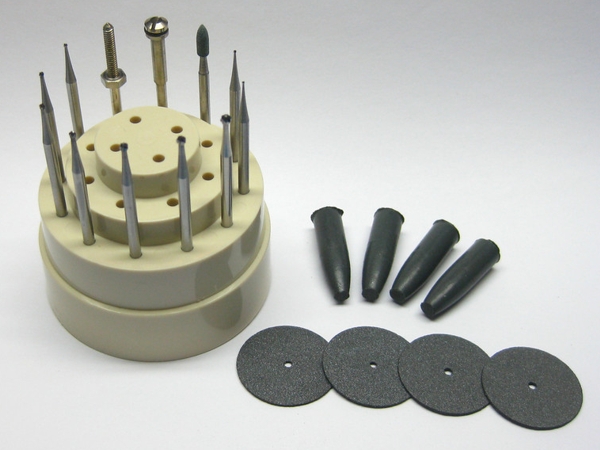

This versatile tool is ideal for milling, drilling, grinding, cutting, and sanding circuit boards.

LEARN MORE

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯