|

Outline

This procedure eliminates or reduces the bow, twist, or warping of circuit boards.

|

|||||||||||||||||||||||||

|

Procedure

Evaluation

|

|||||||||||||||||||||||||

Images and Figures

Bow and Twist Repair

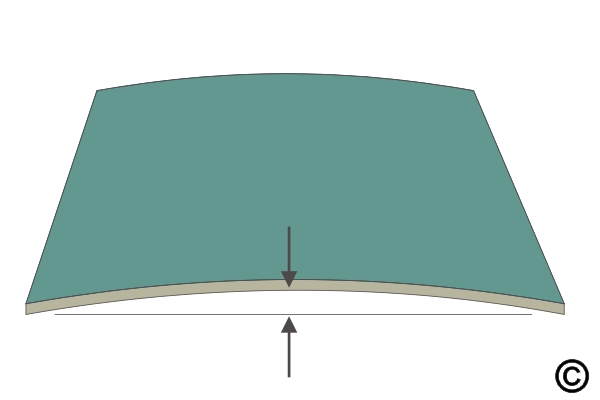

Figure 1. Check the deflection to determine if the rework is needed.

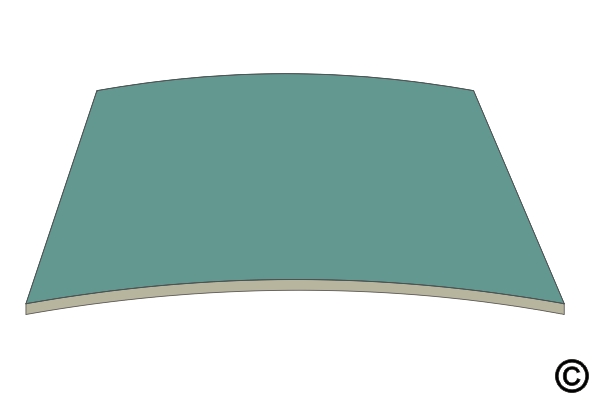

Figure 2. Place the restraint bars along the edges that require rework.

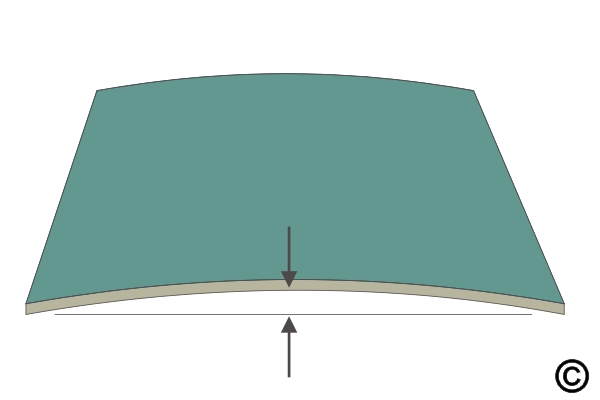

Figure 3. Place the circuit board, restraint bars, and base plate in the oven and bake for 1 hour at 125 degrees C - 257 degrees F.

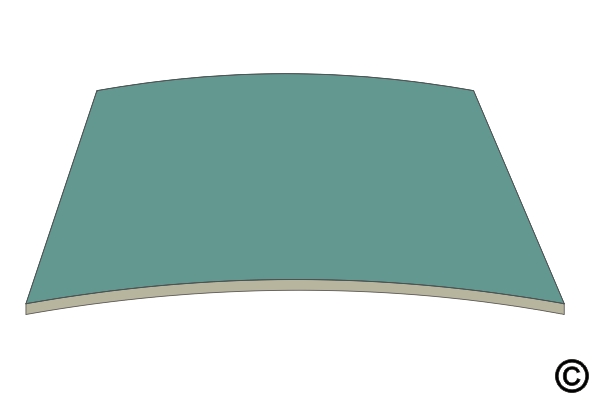

Figure 4. Remove from the oven and allow to cool to room temperature. Remove restraint bars. Check the edge deflection using a caliper or pin gauges.

|

|||||||||||||||||||||||||

3.2 Bow and Twist Repair

This procedure covering bow and twist repair on circuit board assemblies.

Minimum Skill Level: Intermediate

Conformance Level: High

REQUEST FOR QUOTE GUIDES INDEX

Bow and Twist Repair

Check the deflection to determine if the rework is needed.

Place the restraint bars along the edges that require rework.

Place the circuit board, restraint bars, and base plate in the oven and bake for 1 hour at 125 degrees C - 257 degrees F.

Remove from the oven and allow to cool to room temperature. Remove restraint bars. Check the edge deflection using a caliper or pin gauges.

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯