|

Outline

This procedure includes figures and tables for solder joint acceptability criteria on a variety of component types.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Procedure

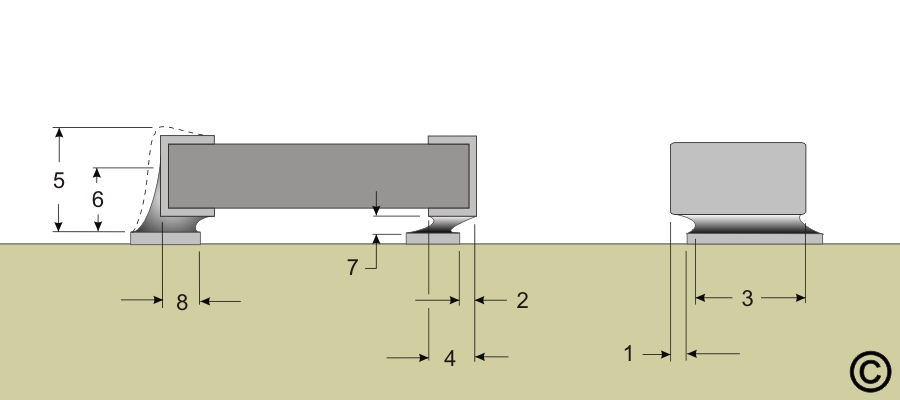

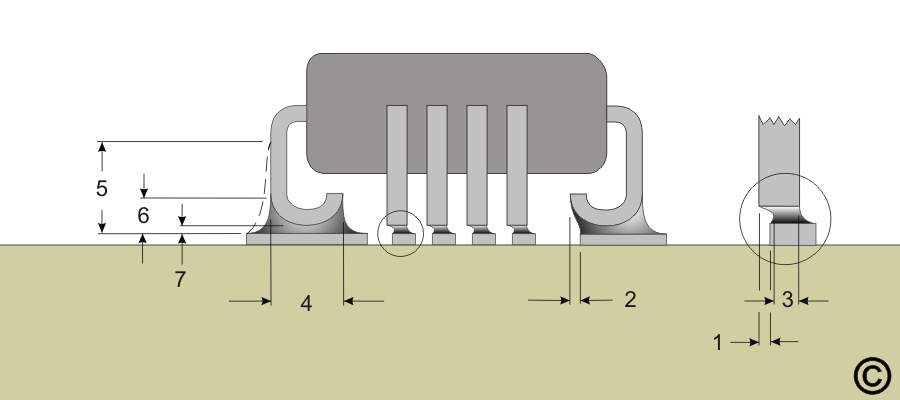

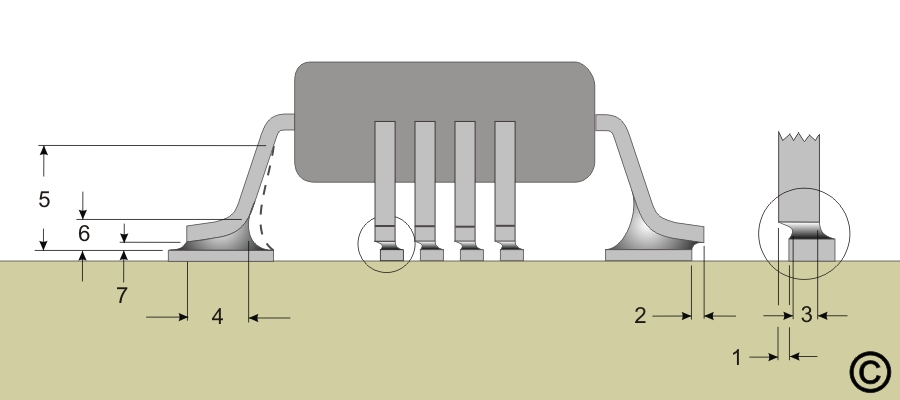

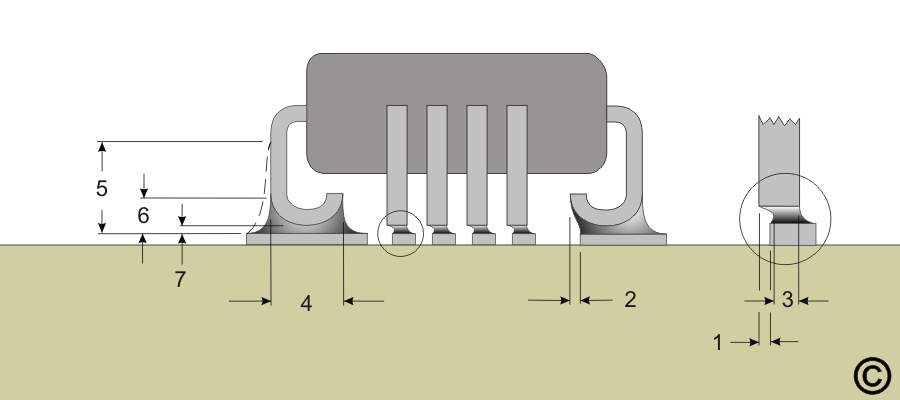

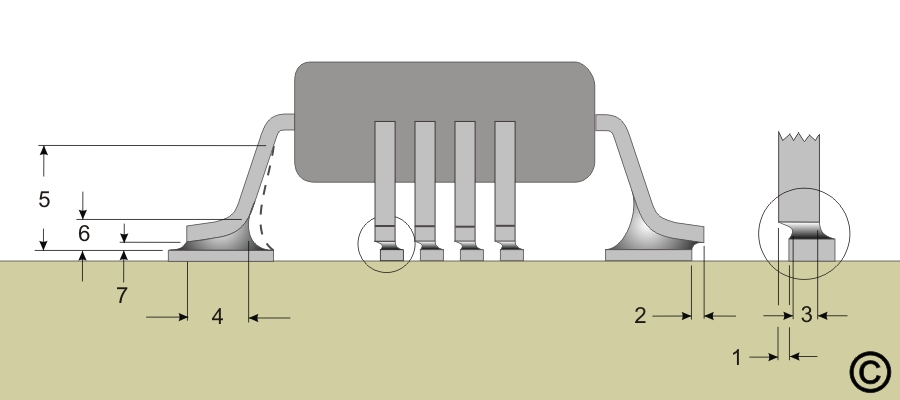

Figure 1: Dimensional Criteria for Through-Hole Components

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Images and Figures

Solder Joint Acceptance Criteria

Figure 1. Dimensional Criteria for Through Hole Components

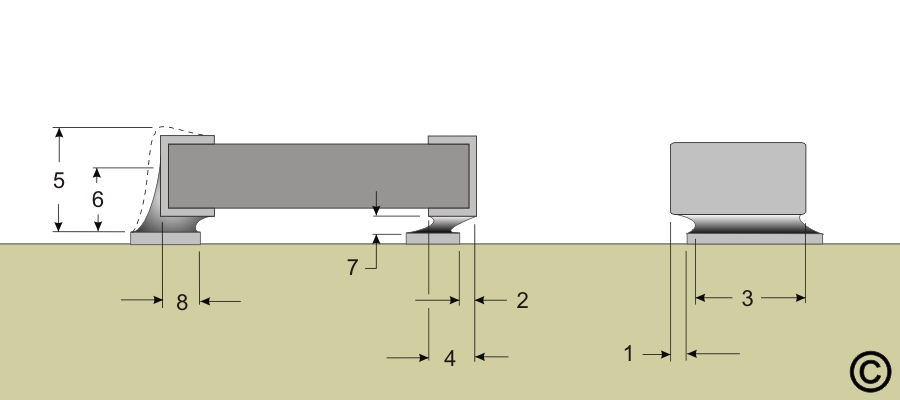

Figure 2. Dimensional Criteria for Chip Components

Figure 3. Dimensional Criteria for J Lead Components

Figure 4. Dimensional Criteria for Gull Wing Components

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7.1.3 Solder Joint Acceptance Criteria

Page covers includes tables and illustrations covering solder joint acceptance criteria on circuit board assemblies.

Minimum Skill Level: Intermediate

Conformance Level: N/A

REQUEST FOR QUOTE GUIDES INDEX

Solder Joint Acceptance Criteria

Dimensional Criteria for Through Hole Components

Dimensional Criteria for Chip Components

Dimensional Criteria for J Lead Components

Dimensional Criteria for Gull Wing Components

We're here to help with all your challenging circuit board and electronic component rework and repair needs.

LEARN MORE

SLIDESHOW STARTING

❮

❯